Our factory mainly produces and sells transformers, circuit breakers, insulators, lightning arresters, power equipment

Share

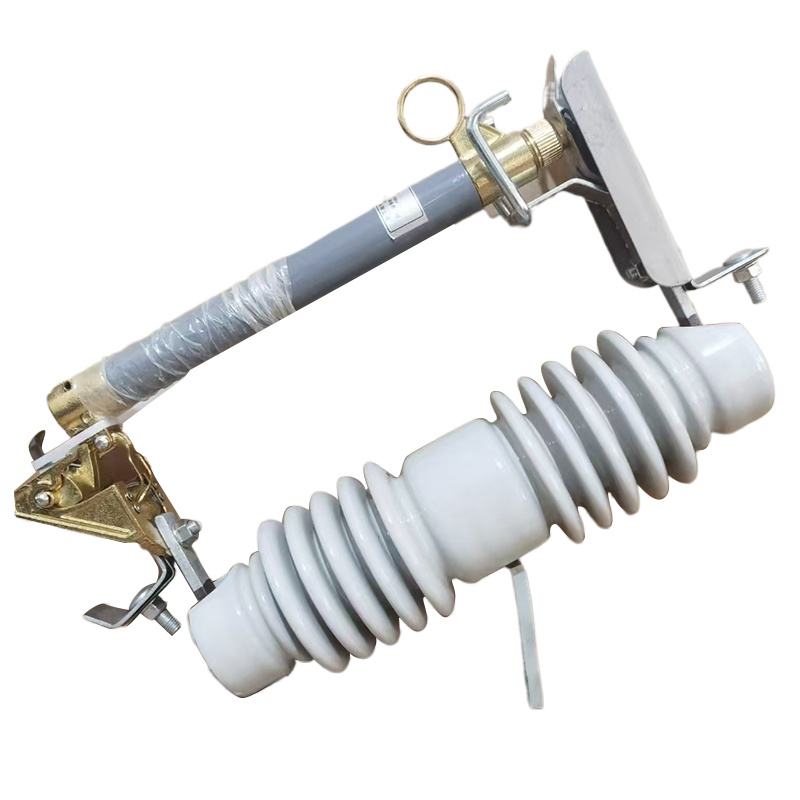

metal fittings

Have you decided yet? Get samples first and contact us!

recommend products

Label

- Product description

-

Fittings, also known as electrical fittings or line fittings, are widely used metal accessories made of iron or aluminum (and other materials) on power transmission lines. These fittings typically need to withstand significant tensile forces during operation, and some also need to ensure good electrical contact. Fittings can be classified based on their functions and uses, mainly including five types: connecting fittings, joint fittings, fixing fittings, protective fittings, and tension fittings.

Connecting fittings: Mainly used to connect conductors, insulators, towers, and other equipment, ensuring the stability and continuity of the entire power system. Commonly used connecting fittings include ball head hangers, bowl head hangers, right angle hangers, U-shaped hangers, etc.

Joint fittings: Used for the connection and joining of conductors, ensuring smooth current transmission. Joint fittings include joint tubes, repair tubes, parallel line clamps, T-type clamps, pre-twisted wires, etc.

Fixing fittings: Mainly used to fix conductors, insulators, and other equipment, preventing them from shifting or falling due to wind, vibration, and other factors. Fixing fittings include suspension clamps, tension clamps, etc.

Protective fittings: Used to protect conductors, insulators, and other equipment from mechanical damage, corrosion, and electrical discharge hazards. Protective fittings are divided into shockproof fittings and insulating fittings, mainly including shockproof hammers, wire guards, damping wires, spacing rods, equalizing rings, shielding rings, etc.

Tension fittings: Used to tighten and fix conductors, towers, and other equipment, ensuring the stability and safety of the power system. Tension fittings include various tension clamps, tension rings, etc.Functions and Roles

Fittings play a crucial role in the power system, and their main functions include:

Connection and Fixation: Fittings can connect conductors, insulators, towers, and other equipment together, forming a complete power system. At the same time, fittings can also fix the position of these devices, preventing them from shifting or falling due to wind, vibration, and other factors.

Protection and Reinforcement: Fittings can protect conductors, insulators, and other equipment from mechanical damage, corrosion, and electrical discharge hazards. In addition, fittings can also enhance the strength and stability of these devices, ensuring the safety and reliability of the power system.

Adjustment and Compensation: In some cases, fittings can also play a role in adjustment and compensation. For example, by adjusting the position or shape of the fittings, the tension and direction of the conductors can be changed; by installing compensators or expansion joints, fittings can compensate for changes in conductor length caused by temperature variations, load changes, and other factors.Application and Selection

Fittings are widely used in power, communication, construction, and other industrial fields. In power systems, fittings are one of the important basic devices to ensure the safe, stable, and efficient operation of the power grid. When selecting fittings, the following factors need to be considered:

Working Environment: The working environment of the fittings has a significant impact on their performance and service life. Therefore, when selecting fittings, it is necessary to consider their working environment, including temperature, humidity, corrosive gases, and other factors.

Conductor Specifications: The specifications and models of the conductors have a significant impact on the selection of fittings. Different specifications of conductors require different models of fittings for connection and fixation.

Load Requirements: Fittings need to withstand certain loads, including the weight of the conductors, wind forces, and loads caused by external factors such as ice and snow. Therefore, when selecting fittings, it is necessary to consider their load requirements to ensure that the fittings can withstand the expected loads.

Safety and Reliability: The safety and reliability of fittings are crucial to the stability and safety of the entire power system. Therefore, when selecting fittings, it is necessary to choose reliable quality and stable performance products, and to follow relevant operating procedures and safety requirements.

metal fittings

Still decided? Get samples firstContact us!

Product Category

Label

RFQ Form

Note: We will contact you within one working day. Please pay attention to your mail.

recommend products

Composite Suspension Insulator